"Nutritional Science and Healthy Diet"

"Nutritional Science and Healthy Diet"

"Nutritional Science and Healthy Diet"

Madhusmita Sahoo, Jamuna Prakash*

Department of Food Science and Nutrition, University of Mysore, Mysuru 570006, India

Corresponding author: Jamuna Prakash,Former Professor, Department of Food Science and Nutrition,University of Mysore, Mysuru, 570006 India; Email: jampr55@hotmail.com

Citation: Sahoo M , Prakash J (2020) Development of HACCP System for Assurance of Product Safety in A Gherkin Pickle Industry. J Nut Sci Heal Diet 1(1): 5-15.

http://dx.doi.org/10.47890/JNSHD/2020/JPrakash/10243801

Received Date: May 27, 2020; Accepted Date: June 10, 2020; Published Date: June 12, 2020

Full Text:

Gherkin (Cucumis anguria), which is being widely grown in India now is processed to produce fermented, fresh pack pickles principally for export market. Hazard analysis and critical control point is a system to ensure good quality and safety of the food products. The present study was planned to develop HACCP system for a gherkin pickle industry along with the assessment of microbial quality for multiple product variations. Eight variants of pickles were prepared using spices and preservative and subjected to microbial analysis on 0, 7th and 15th day following standard methods. HACCP study which included the seven principles and twelve steps of HACCP was carried out with a decision tree protocol. Results showed that there was no growth of E. coli, lactobacilli, yeast or mold even after 15 days of storage in any sample stored at ambient or under refrigeration. The study of HACCP system indicated two critical control points in the whole process of making pickles, namely metal detection and pasteurization, for which the limits were identified.Proper monitoring system for the developed protocol would assure a safe product for human consumption.

Keywords: Gherkin Pickle; Microbial Assessment; Decision Tree; Hazard Analysis; Critical Control Point; Quality Assurance

India is one of the largest producers of fruits and vegetables and caters for both local and global demand. The country exported 2,12,666 MT of cucumber and gherkin to the world worth nearly 205 USD millions during the year 2018-19 with major export destinations being USA, France, Russia, Belgium and Netherland [1]. There is a large demand for some high–value vegetable in the international markets. One such vegetable, Gherkin, popularly known as pickling cucumber, has emerged as a potential export –oriented delicacy, fetching a large amount of foreign exchange every year. Gherkin cultivation was introduced in early 1990’s and now it is grown in four Southern states of India.

Gherkin is not only a pickle of a certain size but also a particular species of cucumber: The West Indian or Burr Gherkin (Cucumis anguria), which produces a somewhat smaller and spiny fruit than the garden cucumber (Cucumis sativus). Standard pickles are made from the Burr Gherkin, but the term gherkin has become loosely used as any small cucumber pickled in vinegar brine, regardless of the variety of cucumber used. Pickled cucumbers/gherkins are categorized as fermented, fresh pack (pasteurized, shelf stable), or refrigerated pickles. These categories account for about 35, 40, and 25% of pickled cucumber products respectively [2]. Fermented gherkins are placed in cover brine syrup containing sodium chloride, calcium chloride and 0.05% acetic acid [3-5].The fermentation of gherkin vegetables is primarily due to the Lactic Acid Bacteria (LAB) present in low numbers on the surface of gherkins which gradually grow in numbers as they are salt and acid tolerant.Fresh pack pickles are made by acidification. Refrigerated gherkin pickles may or may not be fermented before refrigeration. Also, they may or may not be acidified, although mild acidification is highly recommended [6]. Most commercially sold refrigerated pickles are not fermented but are acidified and contain preservative such as sodium benzoate [7].

The food industry uses a variety of preservation, or processing methods to extend the shelf life of fruit and vegetables such that they can be consumed year round, and transported safely to consumers all over the world. Food preservation aims primarily to create a microbiologically safe product, but processers also strive to produce highest-quality food [8]. Traditional food preservation methods such a dehydration, low temperature storage, preservatives, modified atmosphere packaging are well known, another technique used in industrialized as well as in developing countries for effective food preservation, is the hurdle technology, or specifically Hazard Analysis and Critical Control Point (HACCP). Food safety issues are becoming more important in international trade [9]. The microbial safety and stability as well as the sensory and nutritional quality of most foods are based on an application of combined preservative factors (called hurdles). The most important hurdles used in food preservation are temperature (high or low), water activity (aw), redox potential (Eh), acidity (pH), preservatives (e.g., sorbets, benzoates, sulfite) and competitive microorganisms (e.g., lactic acid bacteria) [10]. Use of HACCP in food industry ensures safety of end product, thereby reducing wastages on account of contamination and increasing consumer confidence in the product. Panisello and Quantick [11] have categorized requirements for successful HACCP-implementation into four ‘Pillars’: management commitment, education and training, availability of resources and external pressures (e.g. mandatory requirements of import countries). HACCP protocols are very specific to each commodity and should be developed for each process individually. TheHACCP principles have been employed globally in various food processing industries in the Member States of the European Community for some years to assure safe food production [12,13]. Data available for the HACCP study conducted for Beverage Industry [14] and Noodle Processing Industry [15] shows implementation of HACCP has significant role in ensuring good quality and also assure safety of the food products. However, there is hardly any study found on the food safety and quality aspects of fruits and vegetable sector, especially the acidified food sector into which the pickled cucumber / gherkin is categorized. The present study was planned to develop HACCP system for a gherkin pickle industry along with the assessment of microbial quality for multiple product variations.

Gherkins (Cucumis anguria) of Ajax variety were selected for the development of pickle variants with dill leaves (Anethum graveolens) and spices available locally, in and around Bangalore region. Pickles generally contain ingredients such as salt, vinegar, sugar, spices and water [16]. The other ingredients or additives such as salt, calcium chloride, natural vinegar, colour and the preservative, sodium benzoate was procured from the industrial supply shop and were of food grade.

Cruess [17] described a method of pickling and discussed in detail the various steps associated in pickling process. Similar steps were adopted for the processing of gherkins and dill leaves after the harvest as given below.

Fresh gherkins were procured from the farms within 60 to 80 km periphery of the industry, stored in controlled temperature and processed within 24 hours of the harvest. The dill leaves were procured on day of processing and kept in the cold storage (between 8oC to 15oC) till further processing. The gherkins were sorted, washed thoroughly and visually inspected on a conveyer belt. Fresh dill leaves were also cleaned and washed. Clean, fresh and green gherkins were then graded by size on the basis of count per kg. The grade selected for this study was 60/80 which means the count per kg was an average of 60 to 80 gherkins. Glass jar of 500 ml capacity with 77 mm diameter metal caps were selected to pack the gherkin pickles.

Cover brine is an acidic media, having pH less than 3.2 and is used as natural and artificial preservative for pickles to enhance the taste of the product. Cover brine was prepared using potable water as stated by Sandhuand Shukla [16] with natural vinegar (13% pure acetic acid), salt, colour and the required amount of calcium chloride which is used as firming agent to ensure crispiness post pasteurization [18]. The capping of the jars was done automatically by the Capping machine (model-EMRITO 2.8 and Make-Spain). A minimum 100 mbar vacuum was ensured which is essential for long product shelf life along with an effective pasteurization process. The products developed for all the variants were pasteurized between 80 to 85oC for 12 to 18 min to obtain the minimum core temperature of the gherkin at 70oC, to inhibit/eliminate the viable microbial load (pathogens) and to increase shelf life of product as suggested by Rodrigo and Alvarruiz [19].

Total eight variants of pickled gherkins were developed using fresh dill leaves, dehydrated dill leaves and dill flavour along with spices such as onion and garlic. Few variants were also tried and standardized along with the addition of preservative, sodium benzoate to study the effect of preservative on the keeping quality of the pickled gherkins. The common ingredients for all pickles were Gherkins + water + salt + vinegar +calcium chloride + color. To these, spices, flavours or preservatives were added for variations as given below.

A total of 12 samples from each variant were opened to release the vacuum. Out of 12, six were kept under refrigerated condition (below 4oC) and rest six were stored in ambient room temperature (25oC to 28oC). The samples were analysed for the microbial parameters (E coli, Yeast & mould and Lactobacillus species) on 0-day, 7th day and 15th day of opening the jar following standard methods [20].

The culture media used was phosphate buffer/0.1% peptone water and crystal violet neutral red bile lactose agar with MUG (VRBA MUG). A 25 g of sample was weighed into sterile high-speed blender jar, and blended with 225 ml of diluents. Appropriate dilutions were made using sample homogenate by transferring 1.0 ml of previous dilution to 9 ml of dilution water and mixed well in a vortex mix for 7 sec. A 1.0 ml of aliquot was transferred in duplicate to appropriately marked petri dishes, on which 10 ml of VRBA MUG tempered to 48oC was poured, plates swirled to mix and allowed to solidify. A 5.0 ml of VRBA MUG was spread on top to prevent surface growth and spreading of colonies. The solidified plates were incubated in an inverted position at 35oC for 18-24 hours. The plates were exposed to long wave UV light and fluorescent colonies indicative of E. coli were counted. Typical E. coli colonies appear as dark fluorescent blue when exposed to long wave UV light. The confirmed number of E. coli were determined by multiplying the number of colonies by the reciprocal of dilution and results expressed as E. coli count cfu/g or ml.

Yeast and mold were enumerated by conventional plate count method. The culture media used was phosphate buffer / 0.1% peptone water, DRBC agar and DG18 agar. A 11 – 50 g of sample was weighed and appropriate amount of 0.1% peptone water was added to achieve 10-1 dilution. This was homogenized in a stomacher for 2 min and further dilutions in 0.1% peptone water were prepared. A 0.1 ml of each dilution was pipetted on pre- poured, solidified DRBC agar plates and spread in triplicate. Plates containing 10-150 colonies were counted after 5 days of incubation, or re-incubated if there is no growth for another 48 hrs. Results were reported as CFU/g or CFU/ml based on average count of triplicate set.

The plating medium used for LAB was MRS Agar acidified to pH 5.5 with glacial acetic acid in 2 layers. For inoculation,1.0 ml of inoculums from each dilution was plated in duplicates and incubated at 35oC for 72 hrs.anaerobically. Plates with 25 to 250 colonies were selected for counting. Gram staining and catalase test were used for confirmation of LAB. The number of CFU/g or ml were calculated as a function of the number of confirmed colonies and the inoculated dilution.

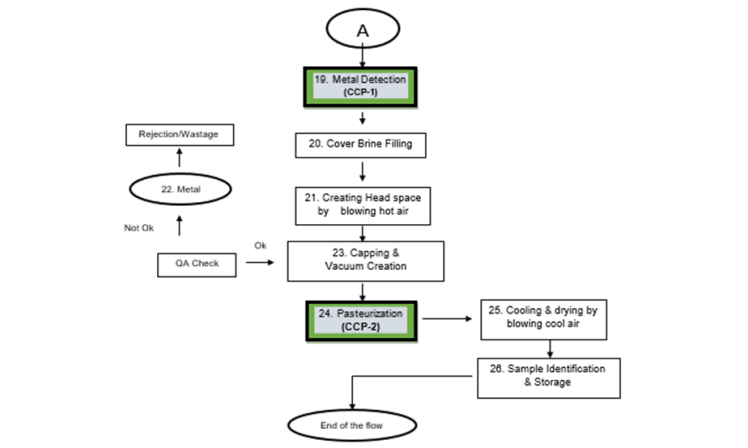

A Codex based approach was followed to conduct the HACCP study which included the seven principles and twelve steps of HACCP. Hazard analysis was carried out and Critical Control Points (CCP) was identified following the decision tree protocol [Flow Chart 1]. The detailed steps are described under results and discussion.

The results of the study are summarized in Tables 1-3 and flow chart 2.

A number of physical, chemical, microbial and enzymatic changes occur during storage of pickles and the environment, i.e. the temperature and humidity in which they are stored, are the major determining factor. According to Etchells et al., [21] the best environment conditions for storage and transport of cucumber would be a combination of low temperature (10oC) with high RH (about 95%). These conditions minimized the undesirable changes of stored pickled cucumbers. These parameters are generally analyzed by the gherkin industries for their commercial products. Microbial assessments are done to ensure safety of products.

The results of microbial examination of pickles in present study are compiled in Table 1. Absolutely no difference was observed in the samples stored at both ambient and refrigerated environment in open condition. Usually, due to high water activity, the gherkin pickles develop yeast and mould. Further, moist environments accelerate the yeast and mould growth consuming the natural sugar content present in gherkins and other ingredients used in the pickles. Hence, refrigerated condition was chosen as one of the storage environments in the study. But surprisingly, no yeast or mould development was noticed in any of the variant in refrigerated condition with moist environment. In case, the thermal processing is not optimum, the pickles develop lactobacillus, a thermophilicbacterium when stored in open condition. All the jars were free from lactobacilli species in both conditions even after kept open for 15 days period, which indicated an adequate pasteurization/thermal processing of the pickle variants. Water was one of the prime ingredients used to develop the pickles and the main source of contamination in water is the presence of E. coli. Hence, E. coli was one of themicrobial parameters tested in all the pickle variants. Absence of the same in the sample jars stored inboth ambient andrefrigerated condition proved that, even after opening, the pickles were safe to eat up to 15 days period when stored at ambient or in refrigerator.

Table 1. Microbial assessment of Gherkin pickles at different storage conditions

|

Sample code |

Parameter (Cfu/g) |

Ambient condition |

Refrigerated condition (2oC-8oC, 35 %RH) |

|||

|

0 Day |

7th Day |

15th Day |

7th Day |

15th Day |

||

|

S1 |

E. Coli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

Lactobacilli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

|

Yeast and mold |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

|

S2 |

E. Coli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

Lactobacilli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

|

Yeast and mold |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

|

SP1 |

E. Coli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

Lactobacilli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

|

Yeast and mold |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

|

SP2 |

E. Coli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

Lactobacilli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

|

Yeast and mold |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

|

SP3 |

E. Coli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

Lactobacilli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

|

Yeast and mold |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

|

SP4 |

E. Coli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

Lactobacilli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

|

Yeast and mold |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

|

P1 |

E. Coli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

Lactobacilli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

|

Yeast and mold |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

|

P2 |

E. Coli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

Lactobacilli |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

|

Yeast and mold |

< 10 |

< 10 |

< 10 |

< 10 |

< 10 |

|

Developing countries are paying increased attention to food safety, because of growing recognition of its potential impact on public health, food security, and trade competitiveness. As developing countries seek to expand agricultural exports especially to overseas countries, many are receiving a wake-up call on the challenges of meeting both government and private Sanitary and Phyto-Sanitary(SPS) standards in export markets. At the same time, increasing globalization of trade introduces greater risks of cross-border transfer of food-borne illnesses. In order to address various food safety concerns in both the spices and fresh and processed fruit and vegetable sectors, some exporters-initiated contract farming operations or ‘vendor screening’ programs. One industry that has been especially successful in establishing contract farming arrangements and meeting stringent food safety and quality standards is the pickled gherkin industry.

A Codex based approach was followed to conduct the HACCP study which included the seven principles and twelve steps of HACCP. Hazard analysis was carried out and Critical Control Points (CCP) was identified following the decision tree protocol.

The product identification details were as follows.

| Product Name | Fresh Pack Pickled Gherkins with Dill and other Indian Spices |

| Composition | Gherkins, water, vinegar, salt, CaCl2, Colour, spices, flavour and preservative (If applicable) |

| Methods of Preservation | Thermal treatment; Pasteurization. |

| End Product Characteristics | Texture, Colour, Flavour, Acidity, Salt, Calcium & pH |

| Packing | Primary packing- 500 ml. capacity Glass Jar |

| Storage Condition | Ambient temperature and refrigeration on opening. |

| Shelf life | Up to 15 days when kept open under ambient and refrigerated condition |

| Customer Preparation | Ready to use and also as an inclusion in sandwiches/ burger etc. |

Vacuum-sealed finished products packed in glass jars developed under this study can be used as ingredient for sandwich/ Pizza, or as independent food or side item as pickle. The intended users of this pickled product do not include any sensitive group of population such as infants, pregnant or old age group. Allergen sensitive people with allergic effect to yellow mustard, yellow 5 (Tartrazine) colour, etc. are advised to take the product with their own risk. However, the product can be used by general public of all age group.

HACCP team was formed covering multidisciplinary five staff members of the factory/facility where the product trials were carried out along with the principal investigator leading the team. The team included core members of facility coming from quality control, pasteurization, production, and maintenance department.

A detailed process flow chart, developed under the HACCP study is given below [Flow chart. 2].

Verification of Process Flow Diagram was done to ensure accuracy and completeness. The HACCP team, mentioned under step III, inspected the operation to verify the accuracy and completeness of the Flow Charts. On Site verification of process flow chart is carried for all the eight variants standardized under the study. The team studied the process flow(s) and suggestions were incorporated in the final flow chart presented under Step IV.

All the hazards identified were analyzed along with the HACCP team by brain storming session. During the analysis, the probability of occurrence of the given hazard and the consequences on occurrence, were examined. For evaluation, a three-stage scale was used on the basis of best industry practice: which included risk/likelihood and consequence /severity as either Serious/high (H), Medium (M), or Weak/low (L). The scale of risk and consequence indicates how serious the given danger is. The dangers that were evaluated by the team were not considered for further analysis, since these can be kept under control while preparing and operating GMP/GHP processes. The detailed HACCP worksheet is compiled in Table 2.

Table 2. Hazard analysis work sheet for Gherkin Pickles

|

Process Step No. |

Process Step |

Identify Potential Hazards, introduced, Controlled or enhanced at this step |

Indicate Likely hood (L) and Severity (S) |

Are any Potential Food Safety /Quality hazard Significant? |

Source of Hazard/ |

Impact of hazard |

What Preventive measures can be applied to prevent the significant hazard |

CCP Decision |

|||||||

|

Q1 |

Q2 |

Q3 |

Q4 |

Q5 |

CCP/ |

||||||||||

|

1 |

Receipt of fresh gherkin |

BioI: |

Pathogens, Borer & rotten |

L-H |

Y |

Material itself, Environment |

May cause illness |

Thorough washing, Pasteurization |

Y |

Y |

N |

N |

N |

NCCP |

|

|

Chem. |

Pesticide Residue |

L-L |

Y |

Material itself, Soil |

May cause |

Use of approved and factory provided chemicals, Pasteurization |

N |

Y |

N |

– |

– |

NCCP |

|||

|

Phy. |

Foreign matters, dust, Fibre etc. |

L-L |

N |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|||

|

2 |

Salt |

Chem. |

Nonfood grade materials, Heavy metals |

L-L |

Y |

Supplier |

May cause intestinal disorders |

Purchase of assured food grade salt from approved vendor |

Y |

Y |

N |

N |

– |

NCCP |

|

|

Phy. |

Foreign matter |

L-L |

Y |

Supplier, Transportation |

May cause illness |

Incoming QC inspection |

Y |

Y |

N |

N |

– |

NCCP |

|||

|

3 |

Vinegar |

Chem. |

Residual Alcohol, Heavy metals |

L-L |

Y |

Supplier |

May cause giddiness |

Purchase of BIS grade material from approved supplier |

Y |

Y |

N |

N |

– |

NCCP |

|

|

Phy. |

Fiber |

L-L |

N |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|||

|

4 |

CaCl2 |

Biol. |

Salmonella |

L-L |

N |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

|

Chem. |

Heavy metals |

L-L |

Y |

Supplier |

May cause illness |

Purchase of BIS quality material from approved vendor |

Y |

Y |

N |

N |

– |

NCCP |

|||

|

Phy. |

Foreign matter, Sand & Fiber |

L-L |

Y |

Supplier, |

May cause |

Incoming QC inspection, |

Y |

Y |

N |

N |

– |

NCCP |

|||

|

5 |

Colour |

Chem. |

Allergen |

L-L |

Y |

Material Itself |

May affect handler’s health |

Follow up of Allergen policy implemented in the facility, |

Y |

Y |

N |

Y |

Y |

NCCP |

|

|

Phy. |

Extraneous Matter |

L-L |

N |

– |

– |

– |

– |

|

– |

– |

– |

– |

|||

|

6 |

Preservative |

Chem. |

Heavy metals, over dosage in the FG |

L-L |

Y |

Supplier |

May cause intestinal disorders |

Purchase of food grade material from approved supplier, Following standardized recipe for cover brine preparation. |

Y |

Y |

N |

N |

– |

NCCP |

|

|

Phy. |

Foreign matter, Sand & Fiber |

L-L |

N |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|||

|

7 |

Flavour |

Chem. |

Presence of chemical contaminants |

L-L |

Y |

Material Itself |

May affect handler’s health |

Purchase from approved vendor, |

Y |

Y |

N |

Y |

Y |

NCCP |

|

|

Phy. |

Extraneous Matter |

L-L |

Y |

Material Itself |

Physical discomfort |

Cover brine filtration |

Y |

Y |

N |

Y |

Y |

NCCP |

|||

|

8 |

Grading & Sorting |

Nil |

– |

– |

N |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

|

9 |

Soaking and washing |

Biol. |

Pathogens |

L-H |

Y |

Water |

May cause intestinal disorder, |

Use of treated water, |

Y |

Y |

N |

Y |

Y |

NCCP |

|

|

10 |

Water |

Biol. |

E.Coli, Coli form |

L-H |

Y |

Bore well |

Diarrhoea, |

Water Treatment, |

Y |

Y |

N |

Y |

Y |

NCCP |

|

|

Chem. |

Heavy metals |

L-L |

Y |

Bore well |

Illness on a longer consumption |

Water |

Y |

Y |

N |

N |

– |

NCCP |

|||

|

Phy. |

Dust & Dirt |

L-L |

Y |

Bore well, dirty pipelines |

Illness |

Filtration |

Y |

Y |

N |

N |

|

NCCP |

|||

|

11 |

Glass Jar |

Phy. |

Foreign matters, dust, etc. |

L-L |

N |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

|

12 |

Jar |

BioI. |

Bacterial contamination |

L-H |

Y |

Water |

May cause illness |

Use of treated water for jar wash, pasteurization |

Y |

Y |

N |

Y |

Y |

NCCP |

|

|

13 |

Gherkin |

Phy. |

Foreign matters, dust, etc. |

L-L |

N |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

|

14 |

Dill Leaves and other Spices |

Biol. |

Salmonella |

L-M |

Y |

Material itself |

Diarrhoea |

Pasteurization |

Y |

Y |

N |

Y |

Y |

NCCP |

|

|

Chem. |

Heavy Metals |

L-L |

Y |

Material |

May lead to body deformity |

Washing and cooking by pasteurization |

Y |

Y |

N |

Y |

Y |

NCCP |

|||

|

Phy. |

Dust & Dirt |

L-M |

Y |

Material itself |

Illness |

Incoming QA check ,washing. |

Y |

Y |

N |

N |

|

NCCP |

|||

|

15 |

Spice |

Biol. |

Pathogens |

L-H |

Y |

Material itself |

May cause illness |

Pasteurization/Heat treatment |

Y |

Y |

N |

Y |

Y |

NCCP |

|

|

16 |

Cover brine preparation |

Phy. |

Dust, thread |

L-L |

Y |

Packaging material of cover brine ingredients |

May cause illness on longer consumption |

Filtration before use |

Y |

Y |

N |

Y |

Y |

NCCP |

|

|

17 |

Cover brine adjustment |

Nil |

|

– |

N |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

|

18 |

Cover brine filtration |

Biol. |

Pathogens |

L-L |

Y |

unclean itself |

Diarrhoea |

Use of clean filter, Low acidity, heating & pasteurization of cover brine |

– |

– |

– |

– |

– |

– |

|

|

Phy. |

Thread, dust from the bags used for salt or CaCl2/ other physical hazard like scissor/ blade used for debagging |

L-M |

Y |

Malfunctioning of filter |

May cause illness on longer consumption |

Use of good quality, cleaned filter, Metal detection for metal hazard |

Y |

Y |

N |

Y |

Y |

NCCP |

|||

|

19 |

Metal detection |

Phy. |

Metal pieces from machineries |

L-L |

Y |

Loose parts, knots & bolts of machines, jewelry |

May cause serious internal organ injury |

Metal Detector |

Y |

Y |

Y |

|

|

CCP-1 |

|

|

20 |

Cover |

Nil |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

|

21 |

Creation of |

Nil |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

|

22 |

Metal |

Phy. |

Dust |

L-L |

Y |

Supplier end, Improper storage |

May contaminate product and cause illness |

Steam washing of cap during capping and pasteurization |

Y |

Y |

N |

N |

– |

NCCP |

|

|

23 |

Capping & |

Nil |

– |

– |

N |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

|

24 |

Pasteurization |

Biol. |

Pathogens |

L-H |

Y |

Product with |

Diarrhea, |

Pasteurization |

Y |

Y |

Y |

– |

– |

CCP-2 |

|

|

25 |

Cooling & |

Nil |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

|

26 |

Sample identification & Storage |

Nil |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

|

Biol.: Biological, Chem.: Chemical, Phy.: Physical. Y: Yes, N: No, L: Low, M: Medium, H: High, CCP: Critical control point, NCCP: No critical control point.

Critical Control Point (CCP) is a handling step, where a control can be carried out, to prevent, eliminate or reduce a possible hazard for food safety to an acceptable level. This control is carried out by: (i) a validated control procedure, (ii) process control by continuous monitoring during the process and (iii) regular verification. The same process was followed to develop all the eight pickle variants. In the entire process, all the three types of hazards (biological, chemical & physical) were evaluated for every step involved in the process. The two steps, which were specifically designed to control the potential physical and biological hazard were ‘metal detection’ and ‘pasteurization’ respectively. There were no further such steps in the process which could control these hazards in the pickle variants. Hence, these two steps were considered as the Critical Control Points (CCPs).

Critical limits were the values that separate the acceptable from the non-acceptable. Critical limits were set on the basis of validated data or as per the national/international standards or on the basis of the best industry practices.

A planned sequence of observations and measurements were placed as effective monitoring system, in order to ensure that the CCP is under control. Records were maintained for every trial taken in actual, for later justification.

An online non-conformity report was raised for any deviation noticed which could lead to the CCP beyond the critical limit. Corrective action was taken within a defined time frame and a preventive action plan was jotted down as precautionary measure for the identified problem. The detailed corrective action taken was closed on the basis of the audit carried out by the HACCP team and closed after the verification of the evidence provided during the audit.

The corrective action taken and the corresponding preventive action documented was on the basis of data published in the scientific literature or as per the industry standard (Best Industry Practices).

Ex. The corrective action taken for a pasteurization failure which could lead to a possible biological hazard in the pickles was rejection/discard of the samples pasteurized. However, the preventive action for the same failure was mainly emphasized on the adherence to a stringent preventive maintenance schedule for the pasteurizer that includes the calibration of temperature and pressure gauges of the pasteurizer and monitoring the temperature of water used in the pasteurizer in all four zones (Zone I- pre-heating, Zone II- heating, Zone III- pre-cooling and Zone IV- cooling ) using a data tracer.

The detailed corrective and preventive action plan documented on the basis of available literature and as per the best Industry practices, is given in the HACCP PLAN FORMAT in Table 3

Table 3. HACCP Plan format

|

HACCP Principles |

||||||||||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

||||||||

|

Step |

Hazard |

Control Point Type |

Critical Limit |

Monitoring |

Corrective Action/Preventive Action |

Verification |

Records |

|||||||

|

What |

Where |

How |

When |

Who |

How |

Who |

When |

|||||||

|

Metal detection |

PHYSICAL |

CCP-1 |

Ferrous –Min.2mm |

Absence of metal contaminants |

At |

Passing each jar through |

At the beginning, end of trial & each change over of variants |

Capping Operator |

Corrective Act |

Reviewing Records |

HACCP Team leader |

Once in a |

1.Metal Detector Calibration 2. On Line process Audit by the researcher |

|

|

Pasteu-rization |

BIOLOGICAL |

CCP-2 |

Temp : 80 to 850C for 12 to 18 min Product core Temp.-Min.700C |

Pasteurizer |

During |

Recording |

Every |

Pasteurizer |

Corrective Act |

Review of online |

HACCP Team leader |

Once in a week |

On Line process Audit by the researcher |

|

Data recorded, were verified and validated through in house and external lab testing.

Data pertaining to corrective and preventive action or verification and validation through analysis, temperature and vacuum set up etc. were recorded.

The complete HACCP Plan of this study indicating seven principles is presented for the two CCPs identified for the developed pickle variants in the Table 3. This completes the development of HACCP system for the gherkin pickle industry.

In conclusion, it can be said that with proper operations the microbial quality of gherkin pickles could be maintained well even during storage for 15 days. The study of HACCP system indicated two critical control points in the whole process of making pickles for which the limits were identified.Proper monitoring system as per the developed protocol would assure a safe product for human consumption.